No Products in the Cart

- WE SHIP WORLDWIDE

- BREXIT RULES APPLY TO EU

- PRICES SHOWN EXCLUDE VAT

- FREE UK MAINLAND SHIPPING ON ORDERS OVER £250*

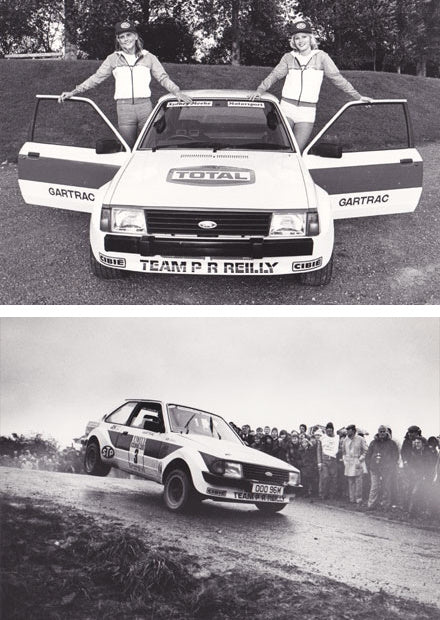

Gartrac is a world renowned motorsport fabrication company with 50+ years' of knowledge and expertise in manufacturing and supplying the highest quality Ford Escort Mk1 & Mk2 rally competition parts and services to the motorsport industry.

Gartrac has worked with all of the major manufacturers over the years in many areas of motorsport, probably the most famous association being with Ford, supplying the works Mk2 Escorts throughout the mid 1970s until the early 1980s.

Gartrac founders David Bignold and Bill Payne first met in 1968 whilst working for Alan Mann Racing in Byfleet, Surrey. During their first year at Alan Mann Racing they worked under the former head of Ford Motorsport development; Len Bailey. They were part of a team of engineers that produced the Escort Mk1 Twin Cam which Australian racing driver Frank Gardner won the British saloon car championship in 1968.

After great success with the Escort Mk1 Twin Cam driven by Frank Gardner, Alan Mann decided to close down his factory in Byfleet, Surrey to concentrate on other business interests. Frank Gardner decided to form a new company picking up where Alan Mann Racing left off. He took Len Bailey with him and Dave and Bill were also offered the opportunity to continue their development work for Ford.

This new company was short lived. By the end of 1969 Frank Gardner decided he wanted to move back to his native Australia. Dave and Bill were in the middle of various projects one of which was the Ford GT70. The project was finished at Gomm Metal Developments in Old Woking, Surrey after Ford stepped in and gave Dave and Bill a place to work.

The Ford GT70 was designed by Len Bailey, it was the direct descendent of the famous Ford GT range of cars which won the Le Mans 24 hours four consecutive years running. The GT70 was a mid engine two seater sports car which had a steel fabricated box frame chassis and a one piece fibreglass body. It was powered by a 2.6 litre V6 cologne engine and 5 speed ZF transmission.

The GT70 was intended for rallying, it competed in several international rallies but Ford decided not to continue the production to concentrate on the development of the Escort.

Towards the end of their time working as self employed contractors at Gomm Metal Developments, Dave worked on Frank Williams Racing's first formula one car and Bill was asked to join the development work on the Gulf GR7 racing car which was later finished at J W Automotive in Slough, Berkshire.

Backing from the toy manufacturer Politoys enabled Frank Williams to build his first in-house Formula One racing chassis which was designed by Len Bailey. The chassis was built at Gomm Metal Developments and the car was finished in the workshop next door by Frank's mechanics. The car was driven by Henri Pescarolo, but unfortunately he crashed and destroyed the car in its first race at the British Grand Prix.

The Gulf GR7 was another Len Bailey designed monocoque sports car using similar suspension components to the Formula One car he had designed. It competed in World sports car races and was sponsored by the major global oil company Gulf.

Dave and Bill had gained valuable experience and knowledge working for Alan Mann and Len Bailey on numerous projects. The pair worked well together and knew it was a great opportunity to start their own prototype metal fabrication business. In 1970 they found a small workshop in Farnham, Surrey and formed Gartrac Fabrications.

The name Gartrac was created from the christian names of their children Gary (Bill's Son) and Tracy (Dave's daughter). They erased the Y off both names and came up with Gartrac. They had a great platform to start their business, already having a good relationship with Ford motor company. This relationship continued immediately with Ford giving them numerous suspension and running gear components such as axle's to modify for Escort Mk1 rally cars.

Gartrac made its first acquaintance with David Sutton who was the manager of Clark & Simpson who were Ford dealers in Sloane Square, London. Ford was about to embark on the 1970 London to Mexico rally using Escort Mk1's. The cars were predominantly standard with no roll cages, however Gartrac supplied uprated suspension and running gear components for the event.

Just prior to the start of the rally Dave Bignold was asked by Ford to travel up to Clark & Simpson and fit rear shock absorber turrets into Rauno Aaltonen's Ford Escort 1850 GT. The installation was completed quickly over a weekend and Aaltonen's car was ready to compete in the rally.

The London - Mexico World Cup rally started at Wembley Stadium in London on April 19th 1970 covering approximately 16,000 miles through Europe and South America and finishing in Mexico City on May 27th 1970. The event was very successful for Ford with Hannu Mikola and Gunnar Palm winning the rally and Rauno Aaltonen and Henry Liddon finishing third.

Gartrac continued developing parts for the Escort Mk1 rally cars. In the early 1970s another famous victory was Hannnu Mikkola and Gunnar Palm's 1972 Safari Rally win in the Escort RS 1600. The pair would take an early lead which they never lost and became the first non-African crew to win the East African Safari Rally.

Throughout the early 1970s, Gartrac modified Escort Mk1 bodyshells for Clark & Simpson in London. These modifications were mainly fitting shock absorber turrets, steel bubble arches and reworking axle's. Gartrac would modify 2-3 bodyshells per week for a number of years.

Gartrac was growing in reputation and the sheer volume of work meant that they needed to move from their small workshop in Farnham, Surrey. They quickly found a new larger workshop in Godalming, Surrey, enabling them to take on more staff, and as a result their output grew dramatically.

Ford had just brought out the Escort Mk2 and realised Gartrac's rapid growth. Ford was looking for a fabrication company that could produce Escort Mk2 bodyshells and parts for their works rally team.

They wanted the Mk2 bodyshells to be identical with a kit of parts that fitted every car; this was not the case with the Mk1. Each drivers' mechanic would have their own idea of the best way to build a car, meaning no two cars would be the same. This caused problems when servicing the cars on events, as parts did not fit universally.

The works Escort Mk1 bodyshells were fabricated by Gomm Metal Developments. These shells were gas welded or nickel bronzed which put great heat and stress into the material, which led to distortion and strength problems. Ford wanted the Escort Mk2 to be welded using the new mig welding process. Gartrac had been using mig welders for some time and this helped secure an initial order for five bodyshells to be produced to their exact specification.

Gartrac duly completed the order and Ford was so pleased with the quality of the workmanship they immediately contracted Gartrac to solely produce Escort Mk2 bodyshells for the works team.

Ford also commissioned Gartrac to produce parts which would standardise the mechanic's build process. They fabricated a large selection of parts such as axle's, radius rods, pedalboxes, fuel tanks and oil tanks and suspension components.

Gartrac was given a free reign at the time to offer suggestions on how Ford could make the cars better and they adopted their suggestions quite readily as the cars were becoming faster, stronger and more reliable.

The designs were changing all the time. Gartrac would make modifications to the axle to improve traction, Ford would then revise drawings to incorporate the changes. They would then produce different variations for Tarmac and Forest applications. The same process was used to develop other parts such as the engine crossmembers, sump shield kits, pedalboxes and suspension parts.

This car was very special, its design contained many modifications to suspension and axle geometry

The lightest rally Escort Mk2 of its time, made especially for Ari Vatanen to drive.

Gartrac produced cars for John throughout his rally cross career. This Mk2 Escort was a clone of the car produced for Martin Schanche previously, apart from the Ford engine which had a Chevrolet Vega cylinder head with larger capacity and produced some 300 BHP.

Gartrac was made aware a year in advance that Ford would be pulling out of world rallying to concentrate on developing the Escort RS1700T. Dave Bignold was invited to a meeting at Boreham and was told the works Escort Mk2 rally production was coming to an end.

However this heralded a new chapter of production of Escort Mk2's. Rothmans, the sponsors of Ford's world rally effort in 1979, wanted to continue its involvement in the sport and formed the Rothmans world rally team which was to run Escort Mk2's for Hannu Mikkola and Ari Vatenen in 1980. The new team was to be managed by David Sutton whom Gartrac had previously worked with through its dealings with Ford dealers Clark & Simpson.

The team would be based at David Sutton Cars in West London and Gartrac was commissioned to carry on production of Escort Mk2 rally bodyshell's and parts for the privately run world rally team throughout the 1980 and 1981 world rally seasons.

This was to prove an extremely demanding period for Gartrac. There was a high turnover of bodyshells being produced at this time and Gartrac had to keep two fully prepared shell's in hand as back up to existing production requirements.

In 1981 Ari Vatanen was crowned World Rally Champion. This success capped a triumphant period and was a remarkable achievement for a privately run team.

David Sutton and his team moved away from Ford and the Escort Mk2 after winning the 1981 World Rally Championship with Ari Vatenan, as it became clear Ford wasn't in a position to offer a competitive car for the 1982 season. His attention turned to securing a deal to run Audi Quattro's in the British Rally Championship and later World Championship events.

During the early 1980s Gartrac worked with David Sutton again with the Audi 80 Coupe and later produced three works Audi Quattro A2 bodyshells which were sent over from Ingolstadt in Germany. Audi usually produced everything in Germany, so this was quite unusual at the time.

The Audi bodyshell's were quite straightforward. Care had to be taken to make sure all the bracketry was absolutely right and the roll cage was fitted correctly for ultimate safety. The work had to meet with German standards, which Gartrac went to great lengths to achieve.

Although the works involvement had ended with Ford, this was an extremely busy period for Gartrac working for other manufacturers such as Audi, GM, Mitsubishi, Toyota and Austin Rover to name but a few.

Looking back, it is hard to imagine how all this work was achieved as Gartrac was still heavily involved in producing and supplying parts for customer Escort's and developing its own projects such as the G3, G6 and G4 Mk3 Escort's.

Ford had finished production of the Escort Mk2 and had unveiled the Mk3 which in standard form was front wheel drive, which at that time was not competitive for rally use. Gartrac decided to convert the Mk3 to rear wheel drive and use as many Mk2 parts as possible.

The G3 had newly fabricated front chassis rails, a wider front track with repositioned top mounts which had the effect of moving the engine and gearbox backwards in relation to the wheelbase. Bespoke front cross member, TCA's and anti-roll bar were designed along with a compression strut system. A fabricated transmission tunnel was grafted through the centre of the car and four link suspension boxes were fitted at the rear with a wider atlas axle. It was powered by a 2.2 litre Ford Pinto engine, with twin-cam head developed by Cosworth.

The G3 was secretly tested at Boreham with the RS 1700T that Ford was developing. It proved to be more than a match, lapping 3 seconds a lap faster around the test track.

The first car produced was prepared by Sydney Meeke Motorsport and driven by Billy Coleman and was very competitive from the outset, setting four fastest stage times on the Cork Rally. The G3 went on to win many domestic rallies and is still competitive to this day.

During the early 1980s the Audi Quattro was the dominant force in Rallycross. The G4 was a result of a pact between Gartrac, Mike Endean who later became the owner of Xtrac and Martin Schanche. The plan was hatched at the British Rallycross Grand Prix at Brands Hatch in 1982 to build a car to beat the Quattro.

Gartrac set about designing a bodyshell and suspension package, Mike went away and designed the 4WD system and Martin was to supply the engine and other parts as well as financial backing for the project. The lightweight bodyshell was heavily modified and designed to house the unique 4WD transmission system with active centre diff, locked by turbo boost, the front diff was housed in the engine sump, the car was powered by a turbo charged Zakspeed engine and had fully independent suspension using McPherson struts and a rear atlas beam axle.

The Gartrac / Xtrac 4WD Zakspeed turbo charged Escort Mk3 made its debut a year later at the British Rallycross Grand Prix at Brands Hatch and demonstrating immediately it was going to revolutionise the rally cross championship.

In 1984 Martin Schanche caused a sensation on the Rallycross scene, dominating the European Championship, he was crowned champion winning 22 races from 28 starts. The Ford Escort was once again the dominant force in Rallycross ending the Audi Quattro domination.

Motoring News - September 1985

This car was a clone of Martin Schanche's European Championship winning car.

In 1985 John Welch won one of the most memorable races in Rallycross history, winning the British Grand Prix at Brands Hatch to the delight of the home fans. John went on to win the 1986 British Rallycross Championship with this car.

John Welch in the Gartrac Rallycross Escort Mk3

The G6 was devised by Gartrac as a road going spin off to the successful G3 & G4 rally & rallycross cars.

Most of the cars produced were rear wheel drive with a 2.8 V6 engine and a Capri / Atlas rear axle. The bodyshell was very similar to the rally car - the only real difference was the road car did not have four link suspension, it ran with an anti-tramp bar set up.

Three cars were produced with 4WD; this employed the running gear, engine and gearbox from a 4x4 Sierra. Gartrac did also produce a few cabriolet versions. Around thirty G6's were produced in total, although many copies were produced around this period.

G3 Escort Advertising Literature and G6 Kit

The Gartrac G6 at the time had phenomenal acceleration and performance and married with unique looks and clever design features really stood out from the crowd.

Both Dave and Bill had G6's as company cars back then and were forever being stopped by the police just so they could take a closer look at the car!

The Capri started life as a Group 1 car, Gartrac then set about extensive modifications.

Terry raced the Capri with great success in the 1980s, winning many races in saloon and thunder saloon car championship events.

This rally car was built in the mid 1980s to compete in National Rally Championship events.

Based on a Ford Sierra XR4i bodyshell, which was modified to accept a Ford GA engine, with ZF gearbox and atlas rear diff assembly but using independent rear suspension with wishbones and uprights.

The engine developed some 450 BHP making the car very competitive.

Dennis Moody in the Gartrac Sierra XR6

David Gillanders owned a large car dealership in Peterhead, Scotland and had been a customer for many years, winning rallies with a Gartrac G3 and also the Group A Scottish Rally Championship in 1985 with a Volvo 240 Turbo.

In 1986 Dave Bignold was invited to a meeting with David Gillanders and the bosses at Austin Rover to discuss running David in a Metro 6R4 competing in the National and Scottish Rally Championships. After a successful meeting, an official team was formed with Gartrac preparing the car and Dave Bignold managing the team which was to be sponsored by British Car Rentals, part of the Rover Group.

Gartrac had a free hand to develop the Metro 6R4, which proved extremely successful with Gillanders winning the National Rally Championship in 1987 and coming runner up in the Scottish Rally Championship.

With nine wins in one year, Gartrac was proud to mastermind Austin Rover's only Championship success.

Gartrac worked for Opel on numerous projects over the years. Below you will find some images of Astra touring cars fabricated at the workshops in Godalming. Gartrac also produced rally car versions of the Astra.

In the 2000s Gartrac worked on Rally Opel Corsa bodyshell's which were jig built on a steel surface plate.

The car panels were delivered in kit form. The floor pan was bolted to the jig first, then the lightweight T45 roll cage was tig welded into place picking up all suspension points to gain maximum strength and stiffness.

After the roll cage was complete, all the other body panels were hand fitted in sequence and welded, before the next one was applied. Final modifications were then completed once the outer shell was in place.

This was a busy period for Gartrac. Historic rallying was becoming increasingly popular and they were still working for major manufactures in rallying and saloon car racing.

Below are some workshop pictures of Almera Rally bodyshell's which were fabricated for Nissan in the late 1990s.

Nissan Almera Fabrication

In the late 1990s, Gartrac was asked to fabricate Nissan Primera touring car bodyshell's for their extensive racing programme in the UK and Europe.

The Primera shell was completely jig built on a steel surface plate to ensure all the geometry was correct. Every effort was made to ensure the shell was super lightweight with maximum rigidity and strength.

This was a very successful period for Nissan, Anthony Reid won seven races in 1998 and finished runner up in the British Touring Car Championship. The following year the Nissan Primera dominated the series with Laurent Aiello being crowned champion and David Leslie runner up.

A spectacular photo of one of the last Gartrac fabricated Rallycross Escort's driven by Barry Squibb.

Having started his career working for Alan Mann Racing in the late 1960s, Dave Bignold was only too pleased to get a phone call from Alan asking whether he would like to produce an updated version of the classic Lotus Cortina that famously raced in the 1960s.

Pictured below, Alan's son Henry Mann, racing the car Gartrac fabricated Lotus Cortina.

David Sutton's Historic Motorsport rally team finally won the East African Rally in 2007, having finished runners up in 2005 with Stig Blomqvist. Gartrac services were again called upon to produce two identical Safari spec Escort Mk1 bodyshell's and a comprehensive spares package for the event.

East African Safari Rally Winners

The cars were specifically designed to cope with the rigours of one of the toughest rallies in the world. The bodyshell was fabricated to a Group 4 specification with a very special lightweight roll cage designed to pick up suspension loads and give maximum safety to the drivers.

Extra provision was made for a larger fuel tank. Front and rear roof bars were fitted to protect the car in the event of a collision with a large animal.

East African Safari Rally

Gartrac had also been developing a new front suspension stub axle, which was designed specifically for motorsport usage. These components debuted at this event with great success and were more than a match for the harsh terrain the cars encountered.

Bjorn Waldegaard led the rally from start to finish in his Escort Mk1, winning the event by nearly 30 minutes. Stig Blomqvist finished sixth in the second Mk1.

Malcolm Wilson, the boss of M-sport, the team which has masterminded Ford's assault on the world rally championship since 1997, flew into Dunsfold aerodrome just outside Gartrac's workshop in Chiddingfold, Surrey, in January 2008.

Malcolm wanted a left hand drive Escort Mk2 Group 4 rally bodyshell for the 2008 Roger Albert Clark Rally. Gartrac had fabricated many cars which Malcolm had driven throughout his career and was honoured to work with him again.

The team at M-sport built a fantastic car which won the 2008 Roger Albert Clark Rally on its first outing, driven by Malcolm Wilson and John Millington.

Malcolm Wilson's Escort

In 2008 former World Rally co-driving champion Phil Mills and ex Historic Motorsport chief mechanic John O'Conner formed Viking Motorsport which specialise in Escort Mk2 Group 4 rally car build and preparation.

The pair wanted the best possible bodyshell and parts to make them competitive from the start. Gartrac was pleased to be involved in the new project and supplied the left hand drive Escort Mk2 Group 4 bodyshell and parts package. The car went on to win the 2009 Roger Albert Clark Rally by over 4 minutes, driven by Gwyndaf Evans and John Millington.

Viking Escort